Calico from spotlight is pretty cheap as well

For anyone wanting to try a slightly different method, I made a small shield a few years back in a similar fashion, but with a different strap system. I oringinally used 6 layers of 'flute, each rotated 60 degrees for ultimate cross-grain support. Coreflute is fairly light, so weight wasn’t an issue. It was still complete overkill, and 4 layers rotated at 45 degrees is fine.

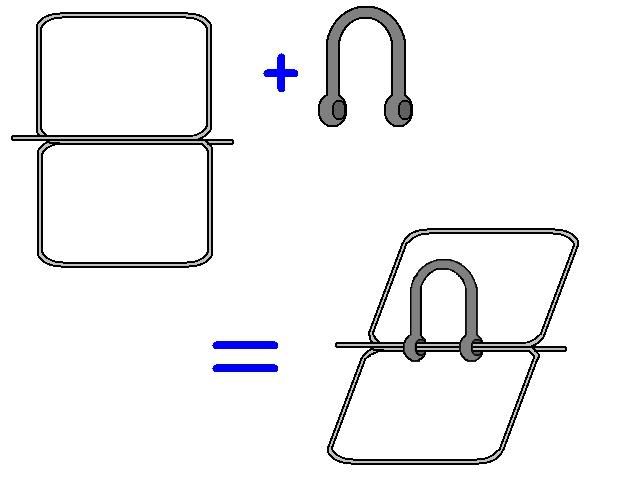

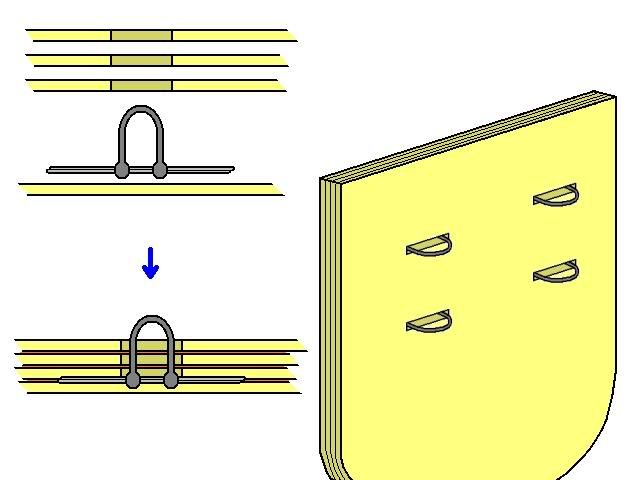

The big difference is in the strap - rather than putting the whole strap through the shield, I made some anchors using D-bolts and wire, bent into a figure-8 frame;

From memory I used fairly small D-bolts, about 30-40mm long. Then, as before you mark where you want your straps, cut rectangular holes through the first three layers of 'flute, and sandwich the whole lot. The net result should be a loop big enough to attach handles or straps to. As always, plenty of glue = win, and because the wire is fairly low profile there’s no need to cut any sort of recess for it or the D-bolt.

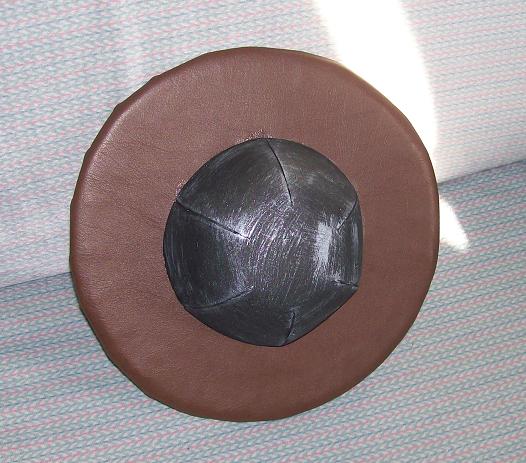

From there, it’s edging and a bit of padding where the arm will be as normal.

Now there’s two reason I like my shields built like this. Firstly, 4 layers of coreflute is awesome, wicked strong, yet still very light. Secondly, having mount-points for the handles and straps means they can be easily replaced, repaired, or even just removed as you need or want to try different handles/straps at your leisure. The first one I did actually had a strap made from dog-leash webbing with a pull-tight thing stolen from my bag, and the handle was a cloth-wrapped piece of garden hose with a short length of yellow nylon rope threaded through to tie on. It was awesome.

The only thing I see bad about doing it this way is that you can’t have a ‘fixed’ grip, built completely rigid to the shield itself, but then I don’t see that as a particularly huge loss.